Sustainability benefits of UV DTF printing are capturing the interest of eco-conscious businesses and consumers alike. As industries increasingly prioritize environmental responsibility, this innovative printing method emerges as a frontrunner in sustainable printing technology. UV DTF printing utilizes water-based inks, reducing harmful emissions and promoting safe production practices. Additionally, its energy-efficient printing process minimizes carbon footprints, making it a viable choice for those looking to bolster eco-friendly printing initiatives. In this article, we delve into the multiple sustainability advantages of UV DTF printing and explore how this revolutionary approach is shaping a greener future for the printing industry.

When discussing the advancements in sustainable printing, UV DTF technology represents a significant shift in the way we approach industrial processes. This modern printing method not only enhances print quality but also adheres to eco-friendly practices, promoting a healthier environment. With its reliance on water-based inks and a rapid curing process, this printing solution is designed to decrease waste and energy consumption. Its versatility allows for a wide range of substrate applications, ensuring minimal resource waste while catering to diverse market needs. In this exploration of sustainable printing techniques, we will uncover the myriad advantages that make UV DTF printing a leader in environmentally responsible production.

Understanding UV DTF Printing: An Overview

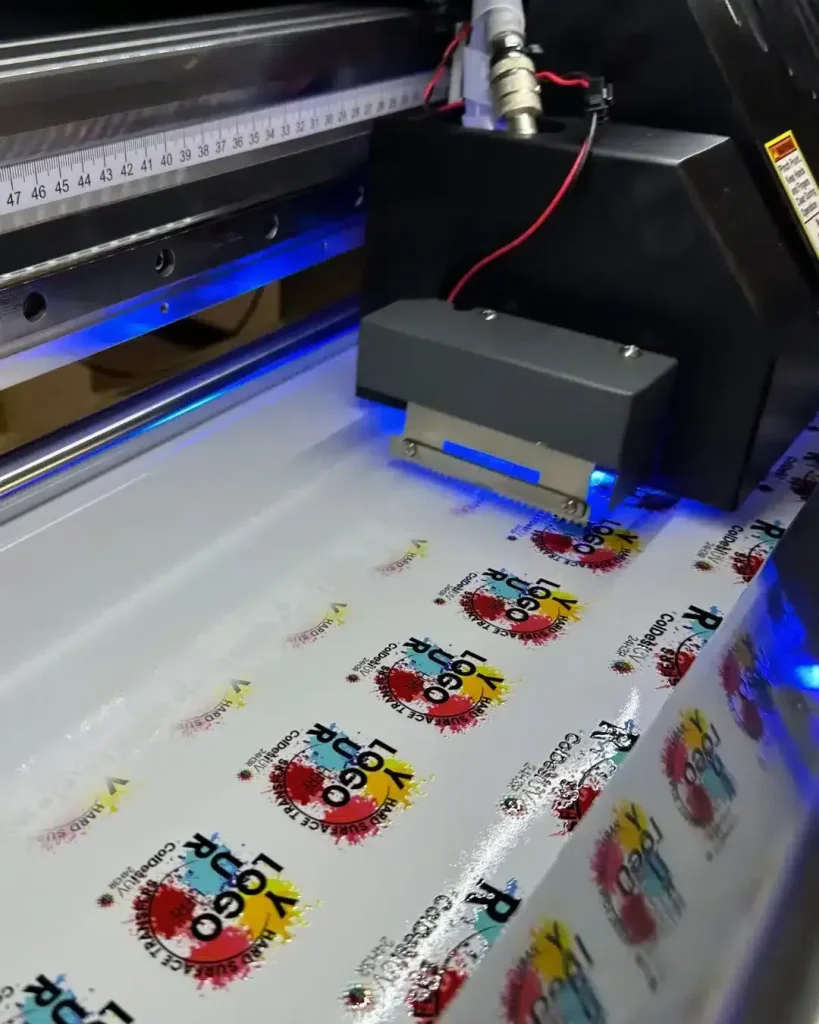

UV DTF (Direct to Film) printing represents a pioneering approach in digital printing technology. Unlike traditional printing methods that often use solvent-based inks, UV DTF utilizes ultraviolet light to cure inks as they are printed onto a special film. This not only enhances the print quality but also limits the environmental impact typically associated with printing processes. The ability to apply vibrant colors and intricate designs directly onto various substrates, such as fabrics and hard materials, showcases UV DTF’s adaptability. As more businesses lean towards eco-conscious practices, understanding this printing technology becomes imperative.

The process of UV DTF printing fundamentally changes how manufacturers operate, allowing for a reduction in material waste and longer-lasting products. Traditional methods often involve various intermediary steps and drying times, extending production cycles. In contrast, UV DTF allows for the immediate curing of inks, making it more efficient. This efficiency translates into lower resource consumption and fits within the broader narrative of sustainable printing technology. By prioritizing quality and eco-friendliness, UV DTF represents a significant step towards responsible manufacturing practices.

Sustainability Benefits of UV DTF Printing

The sustainability benefits of UV DTF printing are increasingly recognized in the industry. One of the main advantages is its ability to significantly reduce ink waste. Unlike conventional printing that often experiences overspray and runoff, UV DTF ensures that ink is applied precisely where needed, minimizing excess. This efficiency not only leads to lower raw material costs, but it also aligns with the global movement towards sustainable manufacturing. Companies adopting UV DTF technology can expect to see a decrease in their environmental footprint, thus contributing positively to ecological conservation efforts.

Additionally, the use of water-based inks in UV DTF printing adds another layer of sustainability. These inks contain fewer harmful elements compared to solvent-based alternatives, which can emit volatile organic compounds (VOCs). Switching to water-based inks means that businesses contribute to improved air quality while also safeguarding the health of their workers and consumers. By prioritizing eco-friendly printing materials, UV DTF printing aligns closely with the increasing demand for sustainable and health-conscious products in the market.

Water-Based Inks: A Greener Choice

The shift towards water-based inks signifies a major advancement in eco-friendly printing solutions. In UV DTF printing, these inks not only offer vibrant color fidelity but also create less environmental and health risk compared to traditional solvent inks. Water-based inks release minimal VOCs, which are notorious for causing air pollution and health problems. Businesses that implement water-based inks are ultimately investing in a healthier future for both their workforce and consumers, while also appealing to the environmentally conscious consumer base.

Furthermore, many manufacturers recognize that adopting water-based inks is not only good for the planet but can also lead to cost savings. These inks typically require less energy for curing compared to solvent-based alternatives, resulting in reduced operational costs. As companies aim to enhance their sustainability practices, choosing water-based inks for UV DTF printing allows them to minimize environmental impact while still achieving excellent print quality. This transition not only positions manufacturers as responsible corporate entities but also fosters long-term customer loyalty.

Energy Efficiency in UV DTF Printing

Energy efficiency is a critical factor in sustainable manufacturing, and UV DTF printing excels in this regard. Unlike traditional printing methods that rely on heating elements to dry inks, UV DTF uses ultraviolet light to cure inks instantaneously. This process significantly reduces energy consumption during production, making it a more sustainable option overall. Companies adopting UV DTF technology can see not only a decrease in energy costs but also a reduction in their carbon footprint, making a positive contribution to environmental sustainability.

Moreover, the efficiency of UV DTF printing translates to faster output with less downtime. As production cycles shorten, companies can respond more rapidly to market demands without sacrificing quality. This increased throughput means less energy is wasted in prolonged production runs. In a world where energy conservation is becoming increasingly paramount, UV DTF printing serves as an exemplary model for industries aiming to optimize their energy use while committing to sustainable practices.

Durability and Longevity: A Sustainable Advantage

Durability is often overlooked in discussions of sustainable practices; however, it plays a significant role in reducing waste. UV DTF printing produces enduring prints resistant to fading, scratching, and wear, making it an ideal choice for applications in high-traffic or high-exposure environments. As these products are built to last longer, the frequency of replacements decreases, which in turn lowers the overall environmental impact from production. This longevity also supports businesses in realizing their sustainability goals, aligning their operations with consumer demands for durable and responsible products.

By investing in resilient UV DTF prints, businesses can maintain their commitment to sustainability while also enhancing their product offerings. The reduction in waste associated with short-lived products positively impacts the overall ecological footprint of the manufacturing process. In industries like textiles and signage where longevity is a priority, UV DTF printing not only fulfills quality expectations but also reinforces an organization’s dedication to sustainable practices.

Current Industry Trends Favoring UV DTF Printing

As we move further into an era where environmental sustainability is paramount, the printing industry is witnessing a notable shift towards adopting UV DTF technology. Recent trends reveal an increasing number of companies investing in UV DTF capabilities not just for operational efficiency, but also due to rising consumer demand for eco-friendly printing solutions. This alignment with sustainable practices fosters a competitive edge, enabling businesses to market themselves as environmentally responsible, thus meeting consumers’ evolving preferences.

In addition to consumer demand, regulatory pressures are also shaping the landscape of printing technologies. Policymakers are pushing for practices that mitigate carbon emissions and promote cleaner manufacturing processes. As a result, UV DTF printing emerges as a favorable option for companies wishing to comply with these regulations while maintaining high standards of print quality. The trend reflects a broader industry commitment to sustainability that provides significant advantages for businesses willing to invest in greener solutions.

Frequently Asked Questions

What are the sustainability benefits of UV DTF printing compared to traditional printing methods?

UV DTF printing offers numerous sustainability benefits, including reduced ink waste, the use of eco-friendly water-based inks, and greater energy efficiency. These factors contribute to lower environmental impact, making UV DTF a more sustainable choice compared to traditional printing methods that use solvent-based inks and extensive drying processes.

How does UV DTF printing reduce ink waste?

UV DTF printing minimizes ink waste by applying ink directly onto the film and reducing overspray and runoff that are common in traditional printing. This efficient use of ink not only lowers production costs but also supports environmental sustainability by decreasing overall material usage.

Are water-based inks used in UV DTF printing environmentally friendly?

Yes, the water-based inks commonly used in UV DTF printing are much more environmentally friendly than traditional solvent-based inks. They contain fewer volatile organic compounds (VOCs), resulting in safer conditions for both the environment and human health, making UV DTF an eco-conscious printing option.

What energy efficiency advantages does UV DTF printing have?

UV DTF printing is more energy-efficient than conventional printing methods because the ultraviolet curing process requires significantly less energy. By curing inks almost instantly, UV DTF printing reduces production times and lowers overall energy consumption, contributing to a smaller carbon footprint.

How do the durability and longevity of UV DTF prints contribute to sustainability?

The durable nature of UV DTF prints means they resist fading, scratching, and wear, which leads to longer-lasting products. This longevity reduces the frequency of replacements, ultimately decreasing waste and aligning with sustainable manufacturing practices.

In what ways is UV DTF printing versatile in substrate applications, and how does this support sustainability?

UV DTF printing is highly versatile, allowing direct application on a wide range of substrates—such as textiles, plastics, and metals—without the need for additional coatings. This versatility not only streamlines production but also minimizes material waste, reinforcing UV DTF printing’s role as a sustainable technology.

| Key Point | Details |

|---|---|

| Introduction | Sustainability is a critical consideration in printing, with UV DTF printing leading the way. |

| What is UV DTF Printing? | A technology that combines digital printing with UV curing for high-quality, eco-friendly prints. |

| Reduced Ink Waste | Minimizes waste of ink by applying it directly to the film, reducing the environmental impact. |

| Use of Water-Based Inks | Water-based inks are safer and less harmful compared to traditional solvent-based inks. |

| Energy Efficiency | UV curing requires less energy, leading to lower production costs and reduced greenhouse emissions. |

| Durability and Longevity | UV DTF prints are highly durable, reducing the need for frequent replacements and waste. |

| Versatility in Substrate Applications | Can print on various surfaces without additional treatments, decreasing material usage. |

| Current Trends | Growing interest in UV DTF technology aligns with consumer demand for sustainable products. |

Summary

The sustainability benefits of UV DTF printing highlight its crucial role in transforming the printing industry towards eco-friendly practices. With significant reductions in ink waste and the utilization of safe, water-based inks, this technology not only minimizes its environmental footprint but also enhances cost efficiency for manufacturers. Energy consumption is notably lower due to the efficient UV curing process, while the remarkable durability of the prints contributes to extended product lifecycles. Furthermore, its versatility in substrate applications streamlines production, indicating a clear shift towards sustainability in manufacturing. As awareness and demand for sustainable solutions grow, UV DTF printing emerges as a key player, encouraging a greener future in printing.