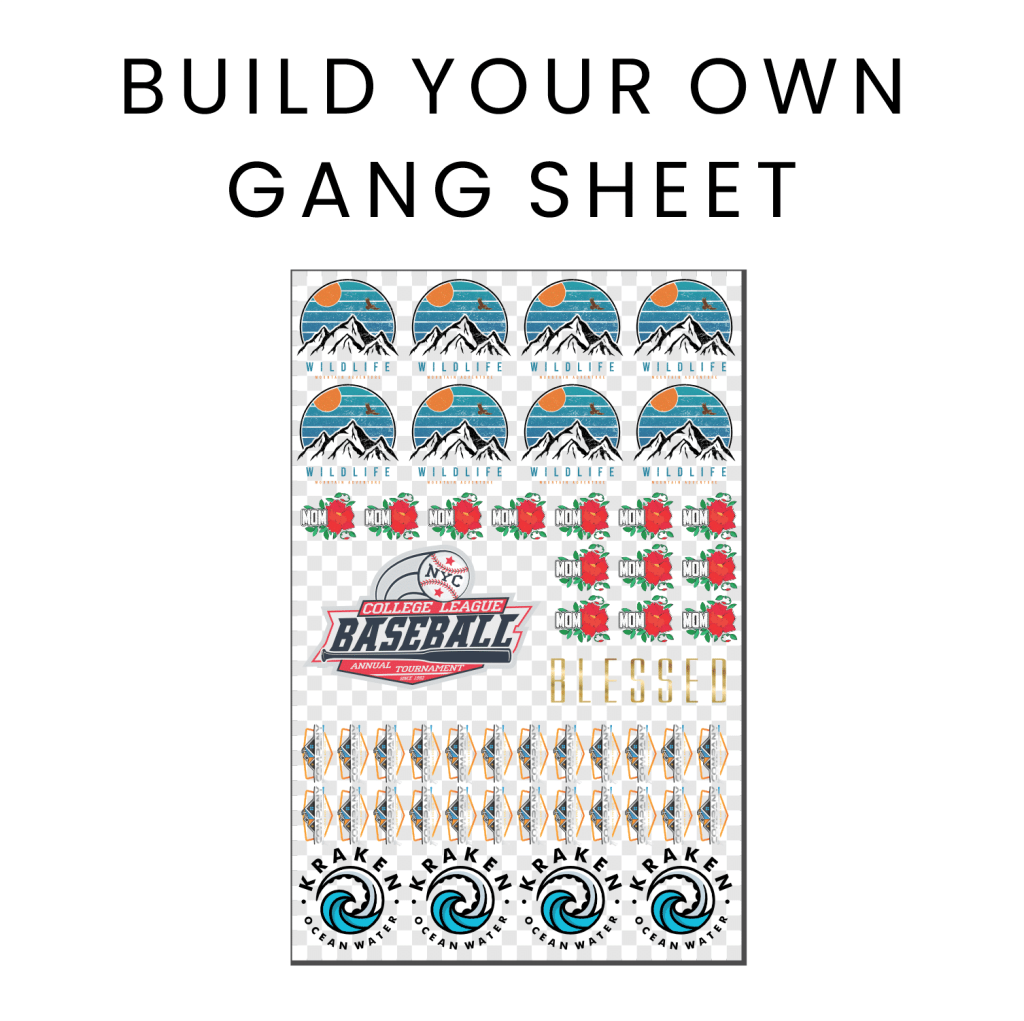

In the fast-paced landscape of textile printing, the DTF gangsheet builder stands out as an invaluable resource for maximizing efficiency and reducing material waste. This innovative tool allows multiple designs to be seamlessly arranged and printed on a single film, streamlining the Direct to Film (DTF) printing process. Not only does this enhance workflow, but it also contributes to significant cost savings, making it a preferred choice among professionals. In this article, we will delve into the array of DTF gang sheet benefits, explore key heat press techniques, and outline textile printing best practices that can elevate your project outcomes. By mastering the use of a DTF gangsheet builder, you can harness the full potential of modern printing technology to create brilliant and durable designs.

When it comes to enhancing textile projects, using a Direct to Film transfer builder can transform the way you approach printing. This advanced tool offers designers the capability to compile various graphics into one master sheet, ultimately fostering improved production efficiency and minimized wastage. As we explore the advantages of employing gang sheets in your creative endeavors, we’ll uncover essential techniques related to heat application and best practices in fabric printing. Whether referred to as a DTF gangbuilder or a design consolidation tool, mastering its functionalities can lead to stunning print outcomes. Join us as we navigate the best strategies for leveraging this technology to its fullest.

Understanding the DTF Printing Process

To effectively utilize a DTF gangsheet builder, it’s essential to have a solid grasp of the DTF printing process itself. DTF, or Direct to Film, allows for images to be printed onto a special film using digital technology, which is then transferred onto fabrics. This process stands out for its ability to create vibrant designs with remarkable durability. Understanding the intricacies of DTF printing will help ensure that designs are aligned perfectly on the gangsheet, maximizing both space and material usage.

Moreover, grasping the DTF printing process enables users to foresee common challenges and streamline operations. The effectiveness of a gangsheet builder is often measured by how well it accommodates different designs and sizes while ensuring that each transfer is of the highest quality. Therefore, mastering the essentials of DTF can significantly enhance one’s ability to navigate and optimize the entire printing workflow.

Benefits of Using DTF Gang Sheet

The benefits of DTF gang sheets are manifold, especially for professionals in the textile printing industry. One significant advantage is the efficiency it brings to production workflows. By fitting multiple designs onto a single sheet, users can reduce waste, lower production costs, and produce a higher volume of prints simultaneously. This not only saves on materials but also maximizes the potential of every printing run.

Additionally, the DTF gang sheet approach promotes versatility, allowing users to combine various designs and products, catering to a broader range of customer demands. Whether working with different colors, sizes, or patterns, the gangsheet accommodates these variations seamlessly. This flexibility can enhance creativity, enabling designers to explore new ideas while maintaining efficiency and quality.

Mastering Heat Press Techniques

Heat press techniques are integral to the success of DTF printing, and utilizing a gangsheet builder effectively means mastering these essential methods. The right temperature settings, typically between 320°F and 350°F, play a crucial role in ensuring that transfers adhere properly to the fabric. As you engage with the gangsheet builder, it’s critical to maintain consistent heat application across the entire design to achieve uniform results.

Moreover, different fabrics may react differently to heat, making it vital to test various materials before committing to a full production run. Adjusting pressure and time is equally important; too much pressure can damage the design details, while too little may lead to inadequate adhesion. By actively refining these heat press techniques, you’ll be better equipped to produce high-quality prints that stand the test of time.

Choosing the Right Materials for DTF Printing

Selecting high-quality materials is paramount when using a DTF gangsheet builder. The right DTF films and inks enhance durability and vibrancy, ensuring that the final product meets industry standards. Investing in reliable materials not only improves print quality but also minimizes the risk of common issues such as fading or adhesive failure, which can undermine your business’s reputation.

Equally important is the compatibility of fabrics intended for printing with DTF methods. Fabrics like cotton or polyester yield excellent results, but it’s crucial to conduct tests to determine the best fit for your specific materials. By understanding the material selection process thoroughly, you can create stunning custom prints that resonate with clients and distinguish your work in the market.

Moreover, understanding the types of inks utilized in DTF printing will allow for better coordination with the DTF gangsheet builder. Implementing the right combination ensures that your designs not only look stunning right after printing but also endure multiple washes and regular wear, which is essential for customer satisfaction.

Troubleshooting Common DTF Printing Issues

Navigating the complexities of DTF printing can sometimes lead to challenges, such as peeling or fading prints. By familiarizing yourself with common issues, you’ll be better prepared to solve problems quickly. A DTF gangsheet builder can be an invaluable tool here; by adjusting designs and configurations, you can preemptively mitigate some issues before they arise during the production phase.

Additionally, having a troubleshooting guide can streamline the resolution process. Whether the problem lies in printer settings or material choices, being proactive can save valuable time and resources. Constantly updating your knowledge and practices will aid in maintaining quality while allowing for continuous improvement in your projects.

Continuous Learning in DTF Printing

Engaging in continuous learning is vital for anyone working in the DTF printing sector. Whether through online forums, industry-specific tutorials, or community workshops, finding resources that explore new techniques can significantly impact your workflow and output quality. Knowledge sharing among industry peers can lead to innovative approaches that can be integrated into your DTF gangsheet building practices.

Furthermore, keeping updated with the latest trends and technologies in textile printing can provide fresh ideas for enhancing your services. By staying connected with the community, you can discover best practices that could set you apart from competitors, ultimately leading to greater efficiency and customer satisfaction. Embracing lifelong learning is not only beneficial for personal growth but also essential for thriving in the fast-paced world of DTF printing.

Frequently Asked Questions

What are the key benefits of using a DTF gangsheet builder in textile printing?

Using a DTF gangsheet builder streamlines the DTF printing process by allowing multiple designs to be printed simultaneously on a single film. This reduces material waste, enhances efficiency, and lowers overall production costs. Additionally, designers can maintain consistent color profiles and optimize layouts, ensuring high-quality outputs.

How do I optimize layouts when using a DTF gangsheet builder?

To optimize layouts in a DTF gangsheet builder, utilize software features that help arrange your designs efficiently. Ensure that graphics are adequately spaced to avoid overlap, and test different placements to maximize the use of film. This practice not only saves materials but also enhances the quality of the final prints.

What materials should I use for DTF printing with a gangsheet builder?

It’s crucial to use high-quality DTF films and inks when utilizing a gangsheet builder. Opt for compatible fabrics like cotton, polyester, or blends that work well with the direct to film transfer process. Testing various materials can help identify the best combinations for achieving durable and vibrant prints.

What printer settings are recommended for using a DTF gangsheet builder?

When using a DTF gangsheet builder, configure your printer according to DTF printing specifications. Adjust settings such as temperature (typically 320°F to 350°F), speed, and pressure. Ensuring proper ink saturation is also key; avoid too much ink to maintain sharp details in your designs.

What heat press techniques should I follow with a DTF gangsheet?

For successful heat transfer when using a DTF gangsheet, adhere to the correct temperature and pressing time—usually between 10 to 15 seconds at 320°F to 350°F. Additionally, apply the right amount of pressure to ensure proper adhesion without damaging the printed design.

How can I troubleshoot issues when using a DTF gangsheet builder?

To troubleshoot common issues in DTF printing with a gangsheet builder, familiarize yourself with potential problems such as peeling or fading. Keep a troubleshooting guide that includes adjusting printer settings, evaluating material compatibility, and modifying application techniques to efficiently resolve issues.

| Key Points | Details |

|---|---|

| Understanding DTF Gangsheet Builder | Essential tool for arranging designs into a single layout for printing, saving materials and improving workflow. |

| Design Efficiency | Optimize layout using templates; ensure color consistency across prints for vibrant results. |

| Material Selection | Invest in high-quality films and inks; ensure fabrics are compatible with DTF methods for better durability. |

| Printer Settings | Correctly configure printer settings for DTF; monitor ink saturation to avoid blurriness. |

| Adhesive Application | Use heat-sensitive adhesives with even distribution for effective bonding. |

| Heat Press Techniques | Follow specified temperature and pressure settings to achieve optimal bonding without damaging prints. |

| Post-Pressing Care | Allow transfers to cool before peeling; conduct wash tests for quality assurance of prints. |

| Troubleshooting Issues | Identify common problems and have strategies ready to efficiently solve them. |

| Educational Resources | Engage with online resources to stay updated on best practices and innovations in DTF printing. |

Summary

The DTF gangsheet builder is essential for streamlining your textile printing projects, leading to enhanced efficiency and reduced material waste. By implementing best practices such as optimizing your design layouts, carefully selecting quality materials, configuring your printer settings properly, and mastering the application techniques, you can achieve superior print quality and production output. Staying informed through continuous learning is vital as the DTF printing industry evolves. Embrace the innovative capabilities of the DTF gangsheet builder to ensure your projects not only meet but exceed customer expectations.