In the vibrant landscape of custom apparel, DTF Transfers (Direct-to-Film transfers) have emerged as a game-changer for T-shirt printing techniques. This innovative method allows for stunning, detailed designs to be printed with incredible precision, making it a favorite among businesses looking to stand out. If you’re passionate about T-shirt printing and aim to elevate your brand through custom apparel, understanding DTF printing is crucial. By harnessing the power of heat transfer printing, you can create unique products that resonate with your customers. Get ready to dive into the world of DTF transfers and transform your T-shirt business today!

Also known as Direct-to-Film printing, DTF Transfers have become increasingly popular as an effective alternative in the realm of T-shirt printing. This method involves transferring high-quality prints onto special film that adheres perfectly to various fabrics when heat is applied. With its capacity to deliver vibrant colors and intricate details, it caters exceptionally well to the rising demand for personalized items in the apparel industry. Heat transfer techniques have revolutionized custom apparel production, making it easier than ever to bring artistic visions to life. If you’re eager to explore cutting-edge printing methods that can boost your custom T-shirt operations, learning about DTF Transfers is the perfect place to start.

The Advantages of DTF Transfers Over Traditional Methods

DTF transfers offer numerous advantages compared to traditional T-shirt printing techniques such as screen printing or direct-to-garment (DTG) printing. One of the standout features of DTF printing is its ability to produce intricate designs with a wide color palette, making it perfect for fulfilling customer demands for custom apparel. The unique process of printing on film allows for sharp details and vibrant colors, which can often be a limitation in other methods.

Moreover, DTF transfers facilitate lower minimum order quantities, which is beneficial for small businesses or start-ups looking to diversify their product offerings without hefty investment risks. The setup for DTF printing is often simpler and requires less time than traditional methods, enabling quicker turnaround times and more efficient workflow management. This efficiency positions DTF printing as a competitive choice in the fast-evolving custom apparel market.

Essential Equipment for Optimal DTF Printing

Investing in the right equipment is crucial for successfully producing high-quality DTF transfers. At the core of this process is a dedicated DTF printer, specifically designed to handle unique DTF inks and transfer films. These printers ensure that your designs maintain both vibrancy and durability, essential traits for satisfying customer expectations.

In addition to the printer, high-quality heat presses play a pivotal role in achieving optimal results during the transfer process. The heat press must deliver consistent temperatures and pressure to promote effective bonding between the fabric and the printed design. Pairing these tools with top-tier DTF transfer film and adhesive powders can drastically enhance your printing quality, providing customers with long-lasting and beautiful T-shirts.

Design Tips for Effective DTF Printing

Creating designs that translate well to DTF transfers involves several important considerations. First and foremost, using graphic design software allows you to manipulate your images for perfect printing. It’s vital to ensure that the resolution is high and the colors are vibrant, as these factors play substantial roles in the outcome of your final product. Additionally, mirroring your designs before printing is a critical step that must not be overlooked; it ensures that your image appears correctly after the heat transfer.

Furthermore, keeping design elements balanced, such as spacing and color contrast, will enable a standout appearance on T-shirts. Always test print on a small scale to evaluate how your design looks on fabric. This practice not only allows for adjustments prior to the main production run but also provides insights into color fidelity and detail retention, enhancing your overall product quality.

Executing the DTF Transfer Process

The process of executing a DTF transfer is straightforward, yet attention to detail is essential for achieving the best results. After printing your design on the film, the application of an adhesive powder while the ink is wet is critical. This step is what allows the design to bond effectively with the fabric during the heat transfer process. If mistakes happen at this stage, it can lead to imperfections in the final product.

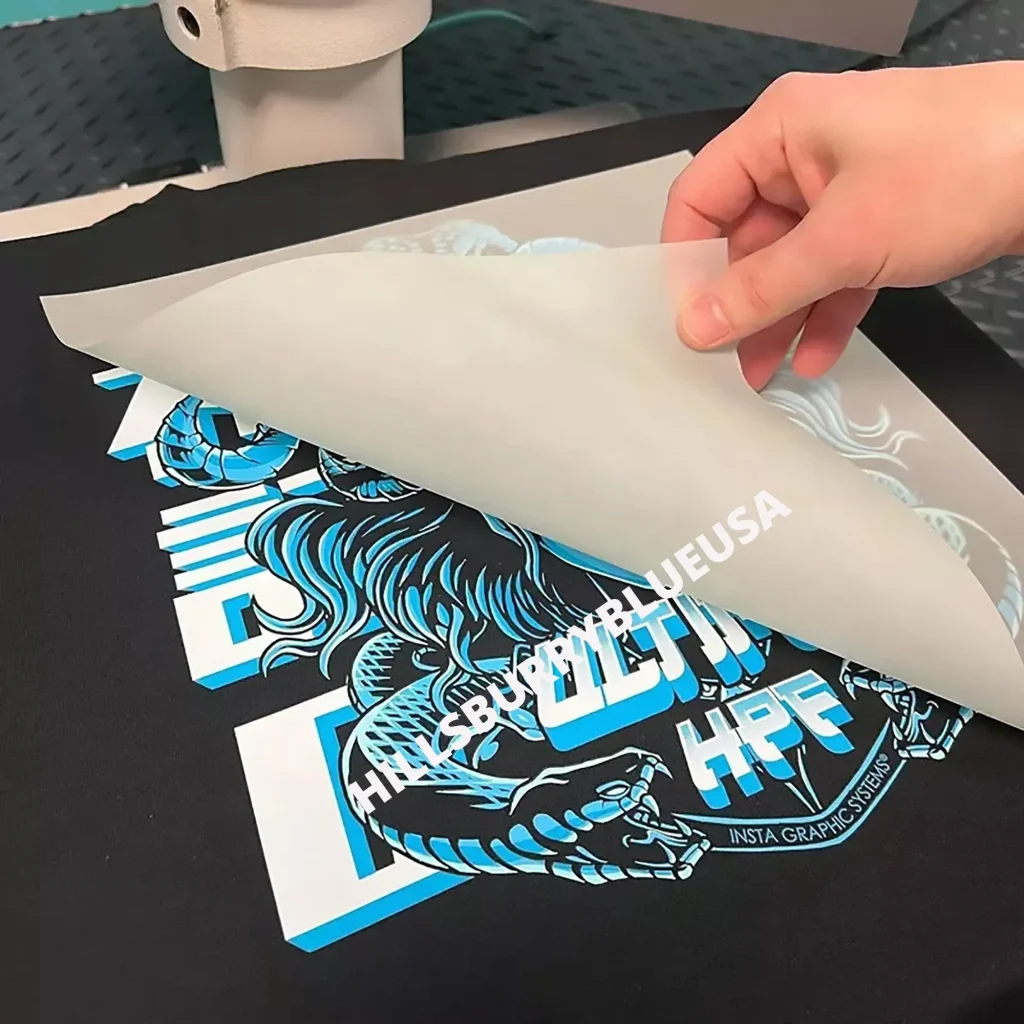

Once the design has been cured, the application stage involves careful positioning on the fabric followed by proper heat press settings. This is the moment where the quality of your heat press becomes crucial, as consistent pressure and temperature will influence adhesion quality. After applying the transfer, allow for cooling before peeling the film; this ensures that the design properly adheres to the T-shirt, giving you a finished product that is visually appealing and durable.

Quality Control and Post-Processing in DTF Printing

Quality control is an ongoing process that starts right after the DTF transfer is completed. Once the film is peeled away, inspect the design for any imperfections, such as uneven colors or areas where the transfer didn’t adhere properly. These factors are crucial not just for aesthetics, but for customer satisfaction, as poor outcomes can result in returns and a damaged reputation.

Additionally, conducting wash tests helps ensure that your DTF transfers maintain their quality after repeated laundering. Customers expect their custom apparel to withstand the test of time, and performing these tests allows you to confidently assure them of your product’s durability. Regular maintenance of your printing equipment and heat press will also contribute to achieving consistent results, fostering a sense of reliability in your T-shirt business.

Expanding Your Custom Apparel Business with DTF Printing

Once you have mastered the DTF printing process, the next step is scaling your custom apparel business. Leveraging social media platforms and e-commerce sites allows your creations to reach a broader audience and attract diverse customer demographics. High-quality images showcasing your DTF-printed designs paired with engaging content can dramatically enhance your brand visibility and customer engagement.

Additionally, consider the importance of branding in your business strategy. Developing a unique identity that resonates with your target market can include personalized marketing tactics, collaborations with local businesses, or offering limited-edition designs. This not only boosts your brand presence but can also lead to increased customer loyalty, ensuring sustainable growth.

Frequently Asked Questions

What are DTF Transfers and how do they work in T-shirt printing?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a special film using a DTF printer. This film is then transferred to fabric using heat, enabling intricate and vibrant designs on custom apparel. The process includes printing, applying adhesive powder, curing the design, and using a heat press to transfer it onto the T-shirt.

What equipment do I need for DTF printing for custom apparel?

To get started with DTF printing, you need a DTF printer, a high-quality heat press, and premium transfer film with adhesive powder. These are essential for achieving high-quality results in your T-shirt printing business.

Can DTF Transfers be used on all fabric types for T-shirt printing?

DTF Transfers work best on cotton and blended fabrics, as these materials allow for effective adhesion and maintain the quality of the print. It’s important to choose the right fabric for optimal results in custom apparel.

What is the process of applying DTF Transfers to T-shirts?

The DTF Transfers process involves printing your design onto a film, applying adhesive powder while the ink is wet, curing the design with heat, and then using a heat press to transfer the design onto the T-shirt. This ensures that the artwork is vibrant and durable.

How do I ensure the quality and durability of DTF printed T-shirts?

To ensure quality, regularly inspect your designs for imperfections after transfer. Conduct wash tests to confirm that the prints withstand multiple washes without fading. Proper maintenance of your equipment is also crucial for consistent results.

What are the benefits of using DTF printing in my T-shirt business?

DTF printing offers several benefits including the ability to produce vibrant, detailed designs, the flexibility to print on various fabric types, and quick turnaround times for custom orders. This makes it a preferred choice for many businesses in the custom apparel market.

| Key Aspect | Details |

|---|---|

| Introduction | DTF transfers are changing custom apparel, allowing intricate designs on T-shirts. |

| Understanding DTF Printing | Involves printing designs on a film and transferring them onto fabric using heat. |

| Equipment Needed | 1. DTF Printer: Designed for DTF transfers. 2. Heat Press: Ensures quality transfer. 3. Transfer Film & Adhesive Powder: Essential for durability. |

| Design Preparation | Create designs using graphic design software; remember to mirror the designs before printing. |

| Printing Process | 1. Print the design onto DTF film. 2. Apply adhesive powder. 3. Cure the design with heat. |

| Heat Transfer | 1. Place the film on the fabric. 2. Use heat press at 305°F for 10-15 seconds. 3. Cool and peel the film. |

| Post-Processing and Quality Control | Inspect for imperfections and conduct wash tests to ensure durability. |

| Expanding Your Business | Utilize marketing through social media and establish a strong brand identity. |

| Key Considerations | Ensure fabric compatibility, understand cost-efficiency, and stay updated with trends. |

| Sources for Further Learning | Check online tutorials and engage with community forums. |

Summary

DTF Transfers play a pivotal role in the custom apparel industry, allowing businesses to create high-quality and vibrant T-shirt designs. By mastering DTF printing techniques, utilizing the right equipment, and implementing effective marketing strategies, you can elevate your T-shirt business to new heights. This guide emphasizes the importance of preparation, quality control, and the understanding of market dynamics to thrive in a competitive landscape. As demand for personalized products grows, leveraging DTF transfers can significantly enhance your creative output and business potential.