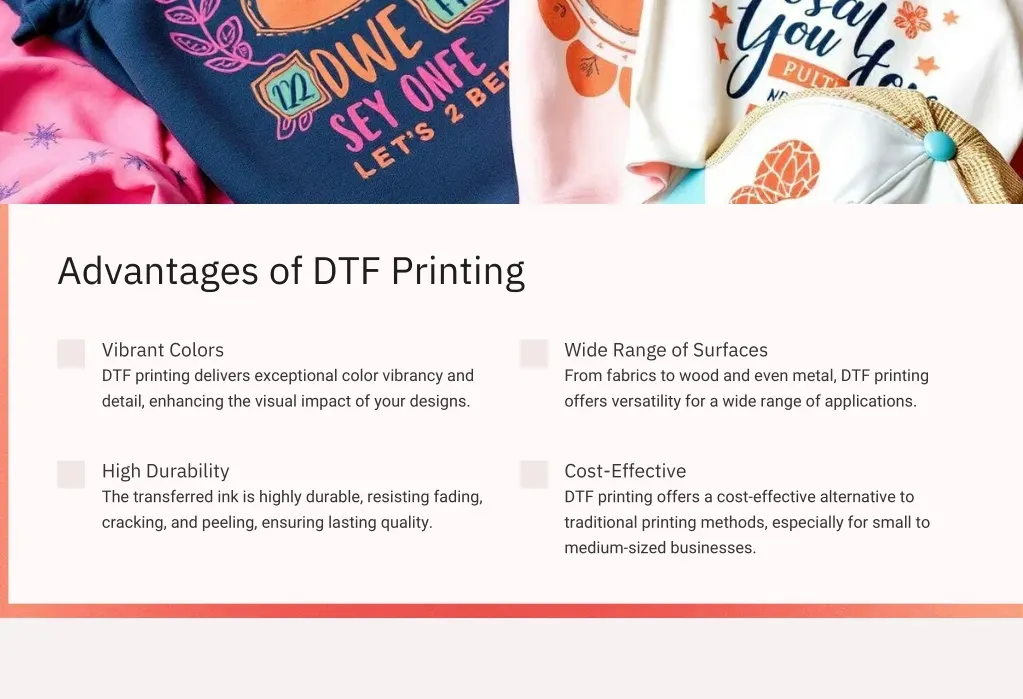

The advantages of DTF printing are revolutionizing the textile industry, presenting a modern solution for both custom printing businesses and garment manufacturers. With its ability to transfer intricate designs onto various fabrics seamlessly, this innovative method emphasizes high-quality textile printing while maintaining an eco-friendly approach with water-based inks. DTF printing benefits extend to cost-effectiveness, especially in smaller batch runs, allowing companies to minimize waste and overhead. Not only does it cater to a broad spectrum of materials, but it also simplifies the printing process, making it user-friendly for newcomers in the custom apparel market. This remarkable technology is quickly becoming a preferred choice for those seeking to enhance their product offerings and embrace sustainable practices without sacrificing quality.

The exploration of Direct to Film (DTF) techniques is reshaping how we tackle textile printing challenges today. This cutting-edge approach offers a plethora of perks, from superior resolution and color vibrancy to an overall adaptable application across diverse fabric types. Businesses venturing into the realm of personalized garment creation find DTF printing to be a lucrative option, especially with the rising emphasis on eco-conscious practices. As we delve into the realm of high-quality designs and cost-efficient solutions, it becomes evident that DTF methods could redefine custom printing standards in the industry. Embracing DTF technology allows for seamless integration of creativity and sustainability, ensuring that emerging businesses stay ahead in the competitive market.

The Rising Popularity of DTF Printing in the Fashion Industry

Direct to Film (DTF) printing has swiftly gained momentum within the fashion industry due to its remarkable ability to produce vibrant, high-resolution designs. As brands and designers strive for eye-catching aesthetics and unique clothing lines, DTF printing stands out as an innovative solution that meets these demands. This process not only enhances the visual appeal of garments but also fosters creative freedom, allowing designers to explore unconventional patterns, colors, and textures without compromising quality.

Furthermore, the fashion industry is increasingly leaning towards personalized pieces that resonate with individual consumer tastes. DTF printing enables businesses to offer custom printing options that cater to this growing demand for unique apparel. It empowers customers to express their identity through personalized designs, which can significantly boost brand loyalty and customer satisfaction.

Frequently Asked Questions

What are the key advantages of DTF printing for custom printing businesses?

DTF printing offers several advantages for custom printing businesses, including high-quality output with vibrant colors, versatility across various fabric types, cost-effectiveness for small batch runs, eco-friendly water-based inks, and an ease of process that simplifies production. These benefits make DTF printing an ideal choice for creating detailed and unique designs.

How does DTF printing compare to traditional printing methods in terms of quality?

One of the primary advantages of DTF printing is its ability to produce high-resolution designs with extraordinary detail and vivid colors. Unlike traditional screen printing, which may struggle with intricate designs, DTF ensures that images are transferred with precision and clarity, resulting in superior quality textiles that stand out in the market.

Is DTF printing a cost-effective solution for businesses with small runs?

Yes, DTF printing is particularly cost-effective for businesses that need to produce small batches. Compared to traditional screen printing, DTF minimizes setup costs and material waste, making it a financially viable option for custom designs and smaller printing jobs, allowing businesses to operate efficiently without sacrificing quality.

What makes DTF printing an eco-friendly option compared to other printing techniques?

DTF printing is considered eco-friendly because it utilizes water-based inks, which are less harmful to the environment than solvent-based inks often used in traditional methods. This aligns with sustainable practices, allowing businesses to reduce their ecological footprint while still producing high-quality printed textiles.

Can DTF printing be applied to various types of fabrics?

Absolutely! One of the standout advantages of DTF printing is its versatility in material application. This method allows printing on a wide range of fabric types, including cotton, polyester, blends, and even specialty materials, enabling businesses to expand their offerings without the limitations imposed by other printing techniques.

What aspects of the DTF printing process make it user-friendly for new businesses?

The DTF printing process simplifies the transition from design to finished product by eliminating the need for extensive pre-treatment of fabrics, which is often required in traditional methods. This straightforward approach makes it user-friendly, especially for new businesses entering the custom garment market, allowing them to focus on creativity without getting bogged down in complex procedures.

| Advantage | Description |

|---|---|

| High-Quality Output | Produces high-resolution designs with vibrant colors that ensure precision and clarity. |

| Versatility in Material Application | Effective on various fabric types including cotton, polyester, and specialized materials. |

| Cost-Effectiveness | Minimizes waste and overhead, making it economical for small batch runs. |

| Eco-Friendly Practices | Uses water-based inks which are less harmful to the environment. |

| Ease of Process | Simplifies the production process, requiring less pre-treatment for fabrics. |

Summary

The advantages of DTF printing position it as a beneficial option within the garment printing industry. This technology allows for high-quality output, ensuring vivid colors and detailed designs, which are crucial for today’s custom apparel market. Its versatility enables the application of prints on a wide range of materials, catering to diverse client needs without restriction. Furthermore, DTF printing proves to be cost-effective, especially for businesses working with small batches while significantly reducing material waste. With eco-friendly practices at the forefront, utilizing water-based inks, DTF printing aligns with sustainability goals essential in today’s market. Lastly, the process’s user-friendliness paves the way for aspiring businesses to delve into custom garment production with less complexity. As the industry evolves, embracing DTF printing could be the strategic move necessary for remaining competitive and innovative.