The DTF Gangsheet Builder is transforming the landscape of garment printing, offering a seamless solution to achieve stunning designs with remarkable efficiency. In today’s fast-paced printing world, the ability to incorporate multiple designs onto a single sheet means businesses can maximize their output while minimizing waste. This innovative tool leverages the Direct-to-Film (DTF) printing process, delivering exceptional print quality that is both vibrant and durable. Whether you’re a small business owner or an established apparel decorator, utilizing a DTF gangsheet builder can significantly enhance your heat transfer printing capabilities. As we delve deeper into the specifics, this guide will equip you with all the necessary steps to master the art of DTF gangsheet printing for perfect results every time.

When discussing the process of printing on garments, many might refer to various terms related to DTF printing technology, such as film-based printing or gangsheet methodologies. These techniques focus on optimizing print efficiency by allowing multiple designs to coexist on a single print sheet, enhancing operational workflows. The flexibility inherent in using a DTF gangsheet builder enables printers to cater to bespoke orders while maintaining high standards in print quality. This approach highlights the advantages of advanced printing methods, showcasing the synergy between artwork design and printed output. As you explore the mechanics of this innovative print technology, you’ll discover not only its practical benefits but also how it can revolutionize custom apparel production.

Understanding the Fundamentals of DTF Printing

Direct-to-Film (DTF) printing has transformed the landscape of garment decoration, allowing for intricate and colorful designs to be leveraged with ease. By printing directly onto a special film, this technique opens doors to creative possibilities, enabling businesses to cater to varied customer needs. Unlike traditional methods such as screen printing, which can be labor-intensive and fraught with color limitations, DTF printing eliminates the need for multiple screens for each color. This distinct advantage makes it a prime choice for small-run projects, ensuring quality without compromising flexibility.

The DTF process begins with high-resolution images, transitioning effortlessly onto film, which can later be heat transferred onto fabrics. This flexibility not only enhances the design process but also allows for quick modifications, making it easy to meet sudden market demands or personalized requests. As DTF printing utilizes innovative materials and technologies, its growing popularity among apparel decorators reflects its superior print quality and durability, setting a new standard in the industry.

The Role of Gangsheet Builders in DTF Printing

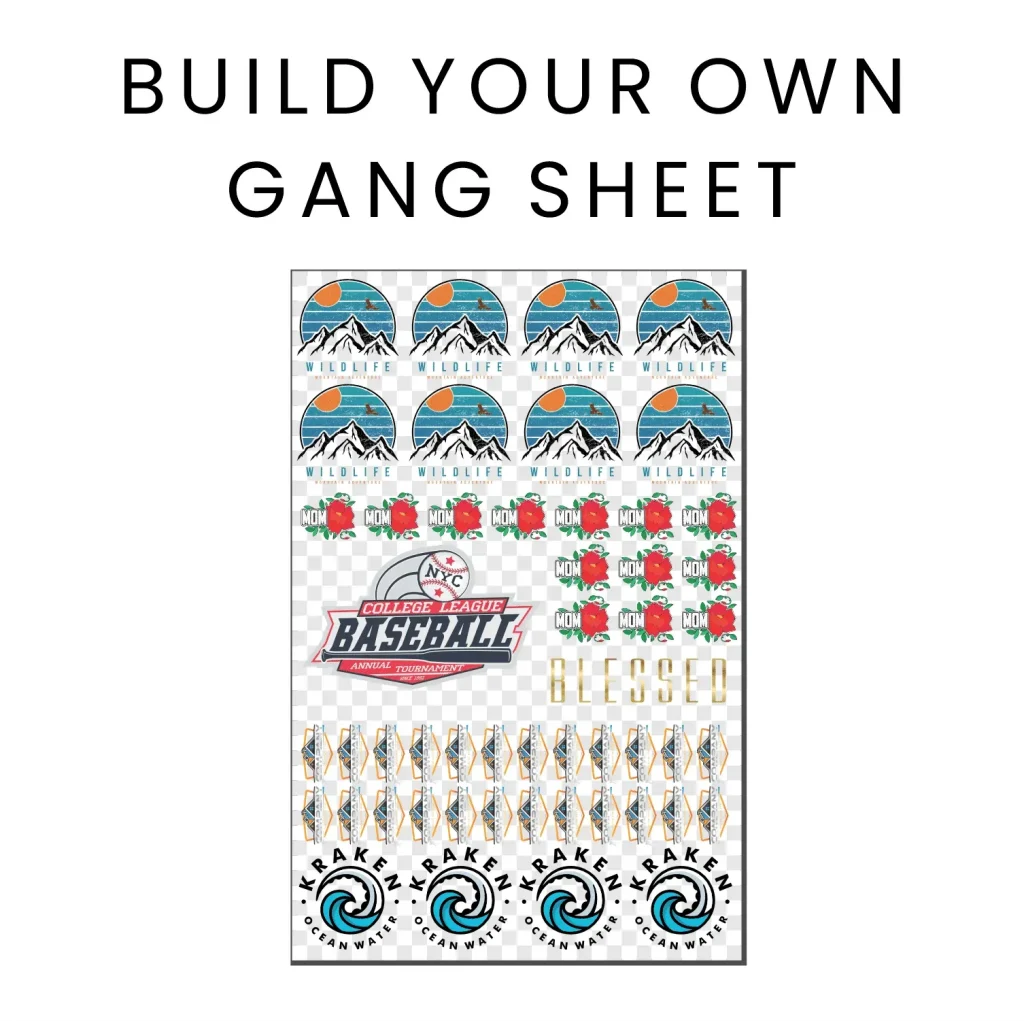

Gangsheet builders play a pivotal role in optimizing the Direct-to-Film printing process. By accommodating multiple images or designs on a single print sheet, gangsheet printing facilitates efficiency in both time and resources. This methodology allows businesses to streamline their operations significantly. With the ability to print a variety of designs simultaneously, companies see a marked reduction in setup time and material waste, translating into higher profit margins.

Incorporating a DTF gangsheet builder into a print shop’s workflow promotes an enhanced level of customization. Businesses can quickly turn around orders of various sizes and designs, meeting the unique demands of their clientele. The gangsheet method inherently supports creativity, allowing designers to explore more complex projects without substantial increases in labor or materials.

Steps to Optimize Your DTF Gangsheet Layout

Creating an effective gangsheet layout is crucial for maximizing print quality and minimizing waste. The first step in the layout optimization process involves meticulous design preparation. High-resolution images are essential, and formats such as PNG or TIFF guarantee clarity and quality in the final print. Utilizing software like Adobe Photoshop or CorelDRAW can greatly enhance design control, enabling users to layer images and structures effectively, ensuring nothing overlaps or is misaligned.

When laying out images on the gang sheet, it’s important to allocate proper spacing and margins that allow for easy cutting and heat transfer application. Employing grid lines and guides in the design software helps maintain a professional look, optimizing the print surface and preventing design distortion during the transfer process. This careful approach not only aids in achieving print precision but also plays a pivotal role in the finished quality of the garment.

Maximizing DTF Print Quality

Achieving high-quality prints in DTF printing is paramount, and several factors contribute significantly to the output quality. Utilizing high-quality pigment inks specifically designed for DTF printers is essential. These inks are crafted to provide vibrant colors that stand the test of time, ensuring that the final product not only looks stunning but also withstands multiple washes without fading.

Moreover, the choice of heat transfer settings plays a critical role. It is essential to adhere to recommended time and temperature guidelines tailored to the type of DTF film and fabric being used, as this ensures optimal adhesion and durability. Regularly calibrating the printer to fine-tune color profiles with Raster Image Processor (RIP) software guarantees accurate color representation, pushing the print quality beyond industry standards.

Benefits of DTF Gangsheet Printing for Businesses

The adoption of DTF gangsheet printing techniques offers a multitude of advantages for businesses engaged in garment printing. Firstly, the method enhances operational efficiency by allowing multiple designs to be printed at the same time. This increase in productivity not only reduces setup time per order but also allows for more business opportunities as turnaround time is significantly improved.

Additionally, gangsheet printing is a cost-effective solution with its ability to minimize material waste. By printing more designs on a single film, businesses can effectively reduce their ink and film costs. This efficiency not only saves money but also aligns with sustainability goals by reducing excess materials and waste in the production process.

Emerging Trends in DTF Printing Technology

With the textile printing industry rapidly evolving, keeping up with emerging trends in DTF technology is crucial for businesses aiming to stay competitive. Recent advancements in DTF inks have led to improvements in vibrancy, durability, and washability. These innovations empower printing companies to offer even higher quality products, catering to an increasingly discerning customer base that demands excellence.

Furthermore, the rise of automated processes within DTF printing is reshaping production workflows. Automation not only enhances speed and efficiency but also reduces the likelihood of human error during printing and transferring processes. Adopting advanced RIP software capabilities can further contribute to more precise management of layouts, making the entire DTF experience smoother and more reliable.

Frequently Asked Questions

What are the key benefits of using a DTF Gangsheet Builder in garment printing?

The benefits of using a DTF Gangsheet Builder include increased efficiency by allowing multiple designs to be printed simultaneously, material savings by minimizing ink and film waste, and enhanced customization options for fast turnaround on personalized orders. This approach streamlines the Direct-to-Film printing process, optimizing resource management and ensuring high-quality print outputs.

How does the DTF printing process work with a Gangsheet?

The DTF printing process with a Gangsheet involves several steps: First, high-resolution designs are prepared and arranged on a gangsheet layout using software tools. Then, high-quality inks and DTF film are used to print the designs. After printing, heat transfer techniques are applied to adhere the prints to garments. This method allows for efficient simultaneous printing of multiple designs, ensuring high print quality.

What software is recommended for creating layouts with a DTF Gangsheet Builder?

For optimal results when using a DTF Gangsheet Builder, software such as Adobe Photoshop and CorelDRAW is highly recommended. Additionally, there are DTF-specific design programs that simplify layout creation. Utilizing these tools helps ensure precise alignment and maximization of space on the gangsheet for efficient DTF printing.

What should I consider for color settings in the DTF Gangsheet Builder?

When using a DTF Gangsheet Builder, it’s crucial to adjust color settings in your design software to ensure vibrant and accurate prints. Utilize Raster Image Processor (RIP) software to manage color profiles tailored to the DTF printing process. Proper color management helps achieve the desired print quality and ensures consistency across multiple designs.

What maintenance is required for printers used in DTF Gangsheet printing?

To maintain consistent print quality in DTF Gangsheet printing, regular maintenance of your printer is essential. This includes running test prints frequently, cleaning printer heads, calibrating color settings, and using high-quality inks specifically designed for DTF printing. Following these practices ensures optimal performance and longevity of the printing equipment.

How do DTF Gangsheet Builders improve print quality for heat transfer printing?

DTF Gangsheet Builders enhance print quality for heat transfer printing by allowing for precise arrangement of high-resolution images, minimizing overlaps and maximizing space usage. This careful layout, combined with high-quality printers and inks, ensures that the prints produced are vibrant, detailed, and durable, making them ideal for heat transfer applications on garments.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A printing technique that transfers vibrant designs onto a special film, allowing for flexible and high-quality results without requiring separate screens for each color. |

| What is a Gangsheet? | A large print sheet for accommodating multiple designs, optimizing printing by reducing waste and costs while increasing efficiency. |

| Step 1: Design Preparation | Use high-resolution images and compatible formats (PNG or TIFF). Rasterize vector graphics for clarity. |

| Step 2: Software Utilization | Utilize specialized software like Adobe Photoshop or CorelDRAW to create and layout gang sheets with proper layering. |

| Step 3: Layout Optimization | Organize designs to maximize space without overlaps and ensure suitable margins for cutting. |

| Step 4: Color and Quality Settings | Adjust color settings using RIP software for optimal print vibrancy and quality. |

| Step 5: Printing Process | Load high-quality pigment inks and DTF film sheets, calibrate the printer, and print at the highest quality settings. |

| Step 6: Heat Transfer | Allow prints to dry before using a heat press, adhering to the recommended settings for durability. |

| Benefits of Gangsheet Printing | Increases efficiency, minimizes material waste, and allows for fast customization of designs. |

| Emerging Trends | Advancements in inks, automation, and RIP software enhance print quality and efficiency. |

Summary

The DTF Gangsheet Builder is an innovative solution for garment printing that allows businesses to produce perfect prints consistently. By leveraging this tool, printers can streamline their processes while maximizing quality and efficiency in output. The approach not only enhances resource management by minimizing waste but also facilitates customization in fast-paced markets. As the world of DTF printing evolves with emerging technologies, utilizing the DTF Gangsheet Builder becomes imperative for companies looking to maintain a competitive edge. As you implement these strategic guidelines, expect improvements in print quality and overall productivity, leading to enhanced customer satisfaction and greater profitability.