In the dynamic textile printing landscape, DTF Gangsheet Builders are revolutionizing how businesses operate by significantly enhancing both efficiency and cost-effectiveness. These innovative tools facilitate the Direct to Film (DTF) printing process, allowing users to maximize material usage while enjoying the myriad benefits of DTF printing. With DTF gangsheet builders, companies can achieve substantial gangsheet printing cost savings, minimizing waste and optimizing every inch of print space. Additionally, these solutions seamlessly integrate with leading DTF printing software, simplifying workflows and driving textile printing efficiency to new heights. As we delve deeper into the capabilities of DTF gangsheet builders, it becomes clear that they are pivotal for any business looking to thrive in today’s competitive market.

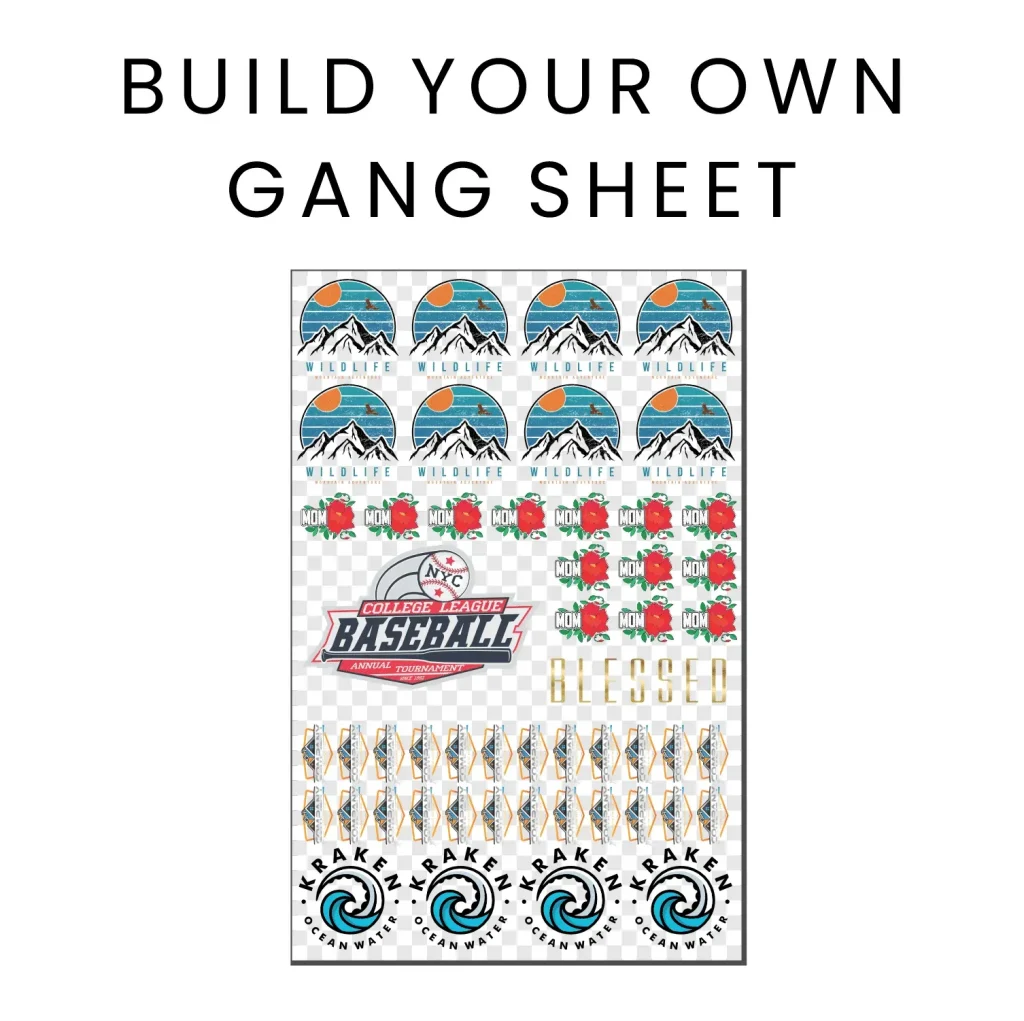

When it comes to optimizing production in textile services, Direct to Film (DTF) sheet builders stand out as a game-changing resource. This process, referred to as gangsheet printing, allows multiple designs to be printed simultaneously on a single sheet, thus streamlining operations and minimizing material waste. By incorporating advanced software designed for DTF printing, businesses can effortlessly manage their production processes, which results in both time and cost efficiency. In the realm of customized apparel manufacturing, utilizing these builders not only reduces operational costs but also enhances creativity and design management for artisans and companies alike. Therefore, understanding the mechanics and advantages of DTF sheet builders is essential for any enterprise aiming to improve their textile production workflows.

Maximizing Material Efficiency with DTF Gangsheet Builders

DTF gangsheet builders significantly enhance material efficiency by allowing multiple designs to be printed on a single sheet. This capability reduces fabric waste and maximizes the utilization of printing materials, which is vital for businesses aiming to keep production costs low. The ability to arrange various designs efficiently not only streamlines the production workflow but also contributes to environmental sustainability by minimizing the resources needed per print run.

In practice, using DTF gangsheet builders means that businesses can accommodate an array of customer requests without over-purchasing or misusing materials. This strategic approach ensures that companies maintain a lean operational model while meeting diverse consumer needs. By incorporating gangsheet techniques into regular printing practices, organizations can optimize their inventory management and deliver products with greater economic and ecological benefits.

Time-Saving Automation: Transforming DTF Printing Workflows

The introduction of time-saving features in DTF gangsheet builders has transformed traditional printing workflows. These automated tools allow users to arrange multiple designs quickly, reducing the time spent on repetitive tasks like resizing and aligning graphics. By automating these processes, businesses can accelerate their production timelines, enabling faster order fulfillment and enhancing customer satisfaction.

Moreover, the reduced processing time achieved through these advanced gangsheet builders provides a competitive edge in a fast-paced market. As customer demands grow and shifts in trends occur, the ability to quickly adapt print outputs ensures that businesses remain relevant and profitable. This capability is particularly crucial for small enterprises trying to establish a foothold in the textile printing industry.

Integrating Design Software for Enhanced DTF Printing Efficiency

The compatibility of DTF gangsheet builders with industry-standard design software, such as Adobe Illustrator and CorelDRAW, facilitates seamless integration that boosts overall productivity. Designers can easily export their creations directly into the gangsheet platform, streamlining the transition from design to print. This direct interaction reduces errors and enhances the precision of the final product, making it easier for businesses to deliver high-quality prints consistently.

Furthermore, efficient design software integration allows for iterative changes to be implemented quickly. As market dynamics shift and customer preferences evolve, having the tools to adapt designs without incurring additional costs or delays can dramatically improve a company’s responsiveness and creativity in textile printing.

Cost Savings Through Strategic Use of DTF Gangsheet Builders

Utilizing DTF gangsheet builders has shown to generate substantial cost savings in printing operations. By consolidating several designs into one print, businesses can minimize their expenses related to ink, material, and labor. This efficiency not only results in lower operational costs but also translates into increased margins for companies striving to maintain competitive pricing with quality offerings.

Studies indicate that integrating gangsheet printing methods can lead to a reduction in overall costs of up to 30-40% when compared to traditional printing methods. This allows businesses to invest those savings back into product development or marketing, fostering growth and enabling businesses to weather economic fluctuations more effectively.

User-Friendly Interfaces for DTF Gangsheet Builders

Modern DTF gangsheet builders are designed with user-friendly interfaces that cater to users of all technical backgrounds. These intuitive dashboards facilitate an easier workflow, allowing operators to manage their designs and printing processes without needing extensive training or technical expertise. This accessibility encourages more businesses to adopt DTF printing technology, leading to widespread improvements in textile printing efficiency.

Additionally, the streamlined interfaces reduce the chances of costly errors that can occur with complicated systems. By lowering the barrier to entry, these innovations empower even small or emerging businesses to harness the advantages of DTF printing technology, significantly leveling the playing field in the competitive textile market.

Embracing Environmental Sustainability with DTF Printing

DTF printing, particularly when enhanced by gangsheet builders, supports environmentally friendly practices in the textile industry. The ability to print on fewer sheets reduces material waste significantly, aligning with growing consumer demand for sustainable products. By implementing these efficient methods, businesses can portray a commitment to ecological responsibility while also positioning themselves as forward-thinking entities within their industry.

As sustainability becomes increasingly important for consumers, incorporating eco-friendly printing practices can give businesses a competitive edge. By leveraging DTF gangsheet printing’s lower energy consumption and reduced waste production, companies can promote their environmentally responsible approaches, appealing to a broader audience and fostering customer loyalty in the long run.

Frequently Asked Questions

What are the main benefits of using DTF Gangsheet Builders in textile printing?

DTF Gangsheet Builders offer several notable benefits, including maximizing material usage by allowing multiple designs to be printed on a single sheet, which reduces waste. They also enhance textile printing efficiency through time-saving features and integration with design software, ultimately delivering significant cost savings in DTF printing operations.

How can DTF Gangsheet Builders help lower gangsheet printing costs?

By optimizing the print process through efficient layout management, DTF Gangsheet Builders significantly reduce the need for excess materials, thereby lowering production costs. This results in gangsheet printing cost savings, making it financially advantageous for businesses focused on profitability and maximizing their return on investment.

What features should I look for in effective DTF printing software that pairs with Gangsheet Builders?

When selecting DTF printing software to use with Gangsheet Builders, look for features such as seamless integration with design applications like Adobe Illustrator, user-friendly interfaces for layout adjustments, and automated design arrangements that save time and enhance productivity in the DTF printing workflow.

How do DTF Gangsheet Builders improve productivity in the design phase of DTF printing?

DTF Gangsheet Builders improve productivity by enabling designers to efficiently manage multiple designs on a single sheet. Their compatibility with leading design software streamlines the import and modification of artwork, reducing the overall time spent on layouts and facilitating faster transitions from design to print.

What are the environmental benefits of using DTF printing with Gangsheet Builders?

DTF printing combined with Gangsheet Builders is considered more environmentally friendly due to its reduced material waste and lower energy consumption. This approach aligns with the growing consumer demand for sustainable products, as businesses can effectively minimize their ecological footprint while maximizing efficiency.

What is the future outlook for DTF printing and Gangsheet Builders in the textile industry?

The future of DTF printing and Gangsheet Builders is promising, with expected growth fueled by an increasing demand for personalized apparel and effective print solutions. Companies leveraging DTF technology are well-positioned to capitalize on market trends, making efficient workflows and cost-effective printing practices essential for staying competitive.

| Key Points | Details |

|---|---|

| Efficient Material Use | Maximizes print area by compiling multiple designs on a single sheet, reducing waste and costs per print. |

| Time-Saving Features | Automated features streamline the design-to-print process for faster turnaround times. |

| Design Software Integration | Compatible with software like Adobe Illustrator and CorelDRAW to enhance productivity. |

| Cost Efficiency | Reduces operational costs significantly, reporting up to 30-40% savings. |

| User-Friendly Interfaces | Easy-to-use dashboards minimize the learning curve for new users. |

| Market Trends | Increased demand for personalized apparel supports the growth of DTF printing. |

| Environmental Considerations | Lower waste and energy consumption make DTF printing a more eco-friendly option. |

Summary

DTF Gangsheet Builders play a crucial role in maximizing efficiency within the textile printing industry. By optimizing material use, streamlining workflows, and enhancing compatibility with design software, these builders contribute to significant cost savings and environmental sustainability. As the demand for personalized garments rises, businesses that adopt DTF gangsheet builders not only improve their operational efficiency but also align with market trends focused on eco-friendliness and customer satisfaction. Embracing this innovative technology allows companies to maintain a competitive edge while providing tailored and sustainable printing solutions.