In the dynamic realm of custom apparel printing, DTF transfers are emerging as a transformative force, reshaping how businesses approach their fabric decoration needs. Direct-to-Film printing technology stands out for its ability to deliver vibrant, intricate designs on various textiles without the high costs typically associated with traditional methods. This innovative printing solution not only enhances quality but also offers significant cost savings and speed, making it a preferred choice among startups and established brands alike. Furthermore, DTF printing is recognized for its eco-friendly printing solutions, providing a sustainable alternative that aligns with the growing demand for environmentally conscious practices in the fashion industry. As we dive deeper, we’ll explore the multifaceted advantages of DTF printing and its profound impact on custom apparel production.

As the custom apparel industry evolves, methods such as Direct-to-Film printing, often abbreviated as DTF, are gaining popularity for their efficiency and quality. This approach utilizes a unique transfer technology that allows for detailed and colorful designs to be applied to various fabric types, including cotton and polyester, without extensive pre-treatment. With DTF printing advantages such as versatility, cost-effectiveness, and faster turnaround times, it has become a go-to option for businesses aiming to meet the demands of modern consumers. Additionally, this printing method supports more eco-friendly practices, contributing to a more sustainable apparel production process. In this article, we will delve into the latest advancements related to DTF technology and why it’s a game-changer in the world of custom apparel.

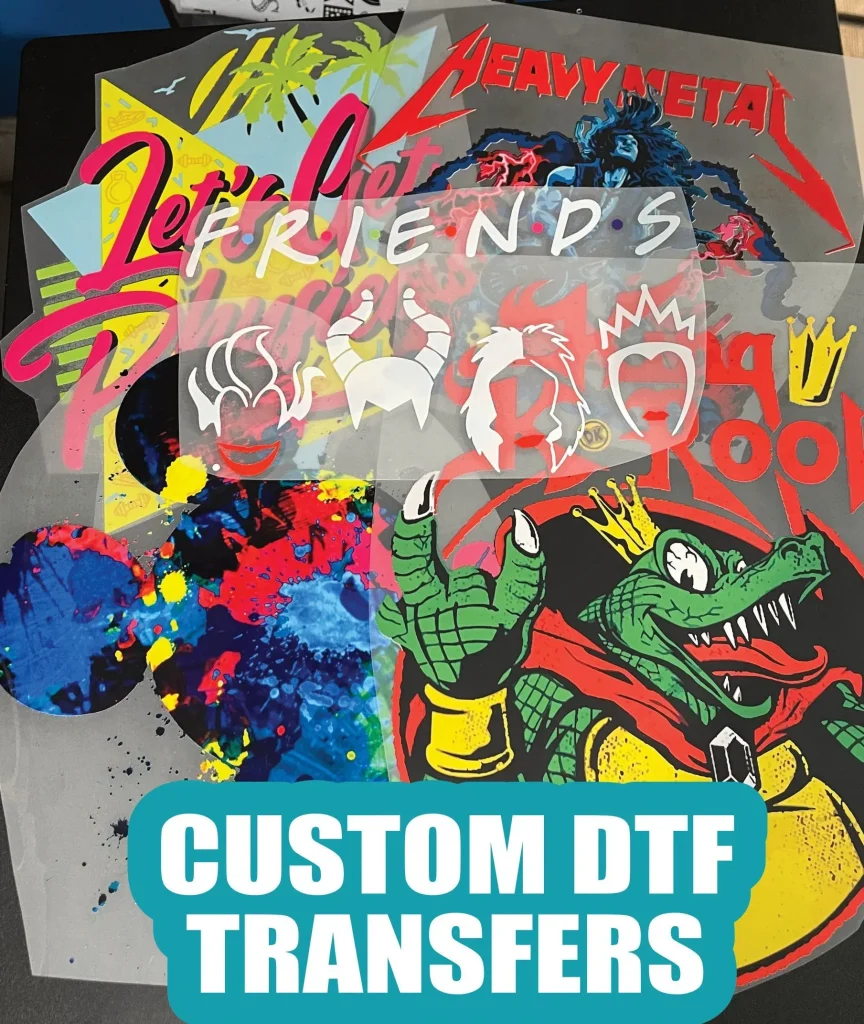

Understanding DTF Transfers in Custom Apparel

DTF transfers, or Direct-to-Film transfers, represent a cutting-edge innovation in the realm of custom apparel printing. This method harnesses advanced printing technology to directly transfer designs onto specialized films, which are then applied with heat to garments. Unlike traditional screen printing, DTF printing does not require screens or pre-treatment of fabrics, leading to simplified production processes and reduced costs. This makes DTF an attractive option for businesses looking to offer high-quality, customized apparel.

Moreover, DTF’s flexibility allows it to print on a wide range of fabrics, including cotton, polyester, and various blends. This versatility means companies can cater to diverse customer needs without being limited by the type of fabric available. The ability to produce vibrant, long-lasting designs with intricate details makes DTF transfers an appealing choice for the current market, where personalization and quality are paramount.

Key Advantages of DTF Printing Technology

The advantages of DTF printing are manifold, making it a compelling choice for businesses in the custom apparel sector. One of the standout benefits is its ability to produce high-resolution images that maintain their vibrancy and clarity even after multiple washes. This quality assurance means customers enjoy beautifully printed clothing that withstands the test of time, fostering brand loyalty and repeat purchases.

Additionally, DTF printing’s cost-effectiveness particularly shines when it comes to small batch orders. Unlike screen printing, which often necessitates substantial initial investments for setups, DTF transfers allow businesses to start without this financial burden. This lower entry point is ideal for startups or small businesses eager to explore their creative potential without overwhelming costs.

Eco-Friendly Benefits of DTF Transfers

In the modern age of sustainability, DTF transfers stand out as a more eco-friendly alternative to traditional printing methods. Many businesses are transitioning towards environmentally responsible choices, and DTF printing aligns perfectly with this trend. Its process generates less waste, as it uses fewer chemicals and eliminates the need for multiple screens, which can be an environmental concern with common screen printing.

Furthermore, the inks used in DTF transfers are formulated to be less harmful to the environment, contributing to a cleaner production cycle. As consumers increasingly demand more sustainable products, adopting DTF technology can enhance a brand’s reputation and appeal to the environmentally-conscious demographic that seeks to make responsible purchasing choices.

How DTF Printing Compares to Other Methods

When choosing a method for custom apparel printing, understanding the differences between DTF and other techniques like Direct-to-Garment (DTG) or traditional screen printing is critical. DTF transfers provide faster speed and efficiency, making them particularly advantageous for businesses that prioritize quick turnarounds. This rapid production capability is essential in responding to fast fashion trends and fulfilling custom orders promptly.

Moreover, DTF printing excels at dealing with intricate designs and vibrant color palettes, often surpassing the quality provided by DTG in terms of durability and detail retention. This makes DTF an optimal choice for brands that require both vivid designs and longevity in the prints.

Recent Developments in the DTF Printing Industry

The DTF printing landscape has witnessed significant growth and technological advancements in recent years. With an increasing number of brands adopting DTF technology, the market is becoming more competitive. Manufacturers are keen to enhance their capabilities through investments in new printer models that offer enhanced speed, improved print quality, and additional functionality, keeping them ahead in a rapidly evolving industry.

Moreover, educational initiatives and training programs have sprung up to support businesses that wish to maximize their use of DTF technology. These resources not only provide instruction on the technical aspects of DTF printing but also foster a community of practitioners that can share best practices and innovations, further boosting the sector’s growth.

The Future of Custom Apparel with DTF Technology

Looking ahead, DTF printing is poised to play a pivotal role in the future of custom apparel manufacturing. As technology continues to evolve, we can expect even greater enhancements in print quality, speed, and sustainability, making DTF an indispensable tool for modern printing businesses. The demand for personalized apparel will likely continue to grow, pushing more companies to explore DTF as their go-to printing solution.

Furthermore, as consumer preferences shift towards more sustainable practices, DTF printing promises to lead the charge by offering eco-friendly solutions that meet market demands. In a landscape where customization and quality reign supreme, mastering DTF technology will provide businesses with a significant competitive advantage in the ever-changing world of custom apparel.

Frequently Asked Questions

What are DTF Transfers in custom apparel printing?

DTF Transfers, or Direct-to-Film transfers, involve a printing technology that applies designs onto special film and can be transferred onto various textiles. This method offers high-quality, detailed prints suitable for custom apparel, making it a preferred choice in the custom apparel printing industry.

What are the advantages of DTF Printing compared to other printing methods?

DTF Printing advantages include versatility with different fabric types, high-resolution prints, cost-effectiveness for small runs, faster production times, and eco-friendly solutions compared to traditional screen printing methods.

How is DTF Printing technology eco-friendly?

DTF Printing is considered an eco-friendly printing solution because it generates less waste than screen printing, which requires many screens and chemicals. DTF minimizes these elements, making it a sustainable choice for businesses aiming for environmentally conscious production.

Can DTF Transfers be used on all types of fabrics?

Yes, DTF Transfers can be applied to a wide variety of untreated fabrics including cotton, polyester, and blends, allowing for flexibility in creating custom apparel without extensive pre-treatment.

What recent developments are occurring in DTF Printing technology?

Recent developments in DTF Printing technology include increased adoption by businesses due to rising consumer demand, investments in advanced printing models for better efficiency, and the availability of educational resources to enhance practitioners’ skills in DTF technology.

Why is DTF printing becoming the preferred method for custom apparel design?

DTF printing is gaining popularity due to its ability to produce high-quality, detailed designs quickly and cost-effectively, along with its eco-friendly attributes and compatibility with various fabric types, positioning it as a modern solution in custom apparel printing.

| Key Points | Details |

|---|---|

| DTF Transfers | A revolutionary printing method gaining popularity in custom apparel. |

| Key Advantages | Versatile in materials, high-quality output, cost-effective, speed of production, eco-friendly. |

| Recent Developments | Increased adoption, investments in technology, growing educational resources. |

Summary

DTF transfers are quickly becoming a pivotal technology in the custom apparel printing industry. As businesses increasingly turn to DTF technology for its versatility, cost-effectiveness, and high-quality results, this printing method is redefining the standards for custom designs. The advancements in DTF technology are setting new benchmarks that enhance production speed and sustainability, making it an attractive option for both startups and established brands. Furthermore, with the industry’s knowledge base expanding through education and training resources, the future of DTF transfers looks promising. Companies that leverage this technology will not only meet customer demands for personalized products but also position themselves at the forefront of a dynamic and evolving market.