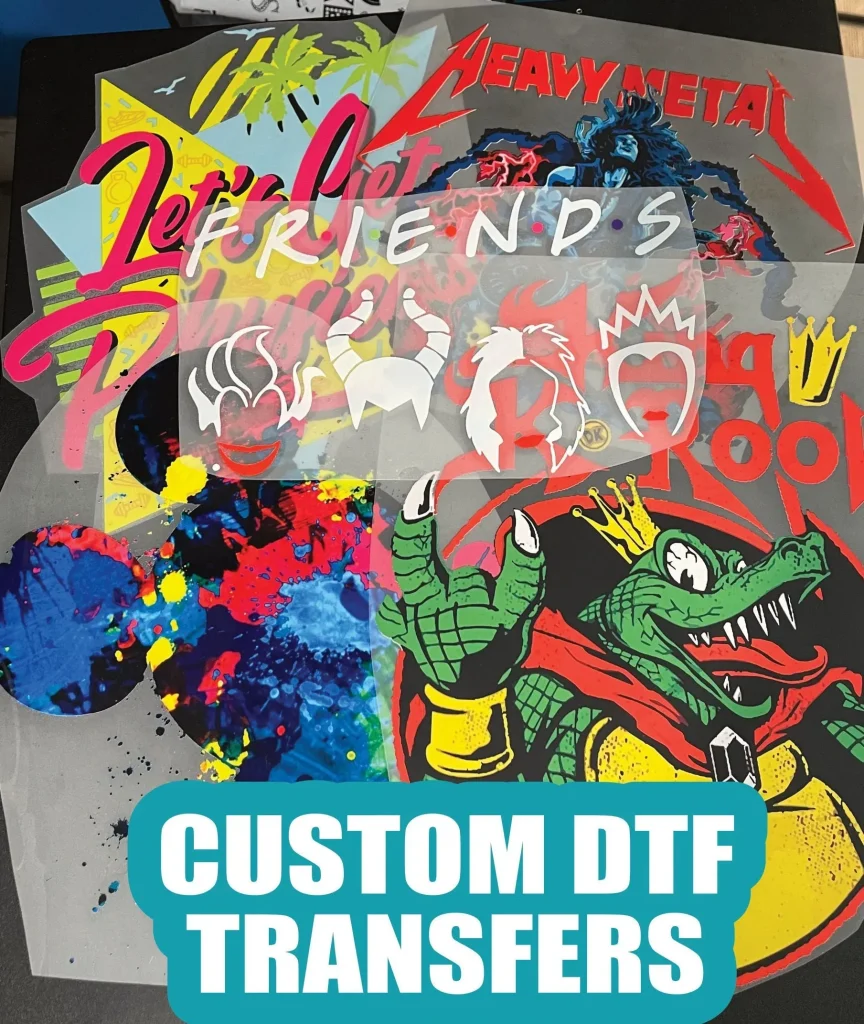

DTF transfers, or Direct-to-Film transfers, have transformed the landscape of custom apparel printing with their innovative approach to high-quality garment designs. This unique method combines vibrant colors and fine details, making it the go-to choice for artists and businesses alike looking to make their mark in the competitive world of custom design. By leveraging DTF printing techniques, creators can produce exquisite prints on various fabric types, ranging from cotton to polyester, ensuring a broad appeal across different market segments. As we embark on this journey to master DTF transfers, we will explore essential heat press techniques and detailed garment printing methods that not only enhance the visual appeal of your creations but also improve their durability. Join us as we delve into the intricate world of DTF transfers and unlock the potential for stunning apparel designs that will captivate audiences.

When it comes to printing on fabric, utilizing Direct-to-Film or DTF technology is a game-changer for those in the custom apparel industry. This printing technique, which allows high-resolution images to be printed onto specialized films, is revolutionizing how designs are transferred to garments. With its ability to achieve vibrant colors and intricate details, DTF offers an exceptional alternative to traditional printing methods like screen printing and heat transfer vinyl. This method not only supports a versatile range of materials but also simplifies the process of transferring stunning designs onto clothing with precision. Throughout this guide, we will examine the nuances of this advanced printing technique and how to effectively implement it into your custom apparel projects.

What are DTF Transfers and How Do They Work?

DTF (Direct-to-Film) transfers are a modern printing method that combines the best features of screen printing and digital printing. This cutting-edge technique utilizes specialized films printed with eco-friendly water-based inks, followed by a hot-melt adhesive that binds the design securely to the fabric. One of the primary advantages of DTF transfers is their versatility; they can be applied to a range of materials, including cotton, polyester, and blends, allowing for unlimited creative possibilities in custom apparel printing.

The process begins with designing your artwork using graphic design software, ensuring it meets the proper specifications for optimal print quality. After printing, the DTF film is cured with adhesive powder, which is then heat pressed onto the fabric. The result is a high-quality, detailed print that exhibits vibrant colors and intricate designs, making DTF transfers a favorite among fashion designers and hobbyists alike.

Essential Materials and Equipment for DTF Printing

To successfully execute DTF transfers, it’s crucial to have the right materials and equipment. High-quality DTF films specifically designed for the printing process ensure that colors remain vibrant and designs adhere effectively to a range of fabrics. High-performance printers, particularly models from Epson, are popular choices due to their ability to accommodate the demands of DTF printing. They provide excellent ink coverage and output fidelity, which are essential for achieving stunning apparel.

In addition to printers and films, the selection of hot-melt adhesive powders is vital. These adhesives are carefully formulated to bond well with both the printed designs and the fabrics. When applying DTG transfers, having a reliable heat press is also essential; it allows the user to control temperature and pressure precisely, guaranteeing a successful transfer. Investing in good quality equipment not only enhances the printing experience but also significantly impacts the durability and quality of the final product.

Step-by-Step DTF Transfer Process Explained

The step-by-step process of DTF printing begins with design preparation, which is crucial for success. Using graphic design software, you can finalize your artwork, making sure it has a resolution of at least 300 DPI to ensure clarity and detail in the final print. After preparing your design, the next step involves printing it onto the DTF film using a compatible printer, taking care to adjust the printer settings to match the specifications needed for optimal results.

Once the design is printed, it’s time to apply the hot-melt adhesive. This step involves applying the adhesive powder while the ink is still wet, allowing it to bond effectively to the design. After this, curing the adhesive by applying heat through a conveyor dryer or oven prepares the film for a successful transfer. Following this, using a heat press to firmly apply the design to the fabric for a specified time ensures that the print adheres properly, thus completing the DTF transfer process.

Advantages of Utilizing DTF Printing for Custom Apparel

DTF printing brings numerous advantages to custom apparel printing, making it a popular choice among designers. One of the most significant benefits is its versatility; DTF transfers are compatible with various substrates, enabling the creation of designs on multiple material types without compromising on quality or vibrancy. This flexibility allows creators to explore innovative designs across different fabric styles, from t-shirts to hoodies.

Moreover, DTF printing enables intricate detailing and vivid colors, leading to professional-grade results that rival traditional printing methods. Unlike direct-to-garment (DTG) printing, DTF is often more cost-effective for small batch orders, making it an attractive option for businesses and individual creators alike. With lower setup costs and the ability to produce high-quality prints on-demand, DTF printing provides a sustainable pathway for those entering the custom apparel market.

Market Trends: The Rise of DTF Transfers

The DTF transfer market is witnessing exponential growth, primarily driven by an increased demand for personalized and unique printing solutions. Major suppliers have begun offering DTF transfer services, appealing to both large businesses and individual creators looking to capitalize on the growing trend. The rise in popularity of on-demand printing services has opened doors for smaller players in the industry, encouraging creativity and innovation.

Advancements in technology are making DTF printing more accessible, with new materials and printers being developed to streamline the process. As the industry continues to evolve, it’s essential to stay updated on the best practices and latest innovations in DTF transfer methods. This proactive approach is vital for anyone looking to distinguish themselves in the competitive world of custom apparel printing.

Mastering DTF Transfers: Skills and Techniques

To truly master DTF transfers, one must develop a deep understanding of various heat press techniques, as the right approach can make all the difference in achieving stunning results. Knowing the proper temperature settings and pressure levels helps ensure that the designs bond well with the fabric and withstand wash cycles without fading or peeling. Additionally, familiarity with garment printing methods allows printers to adapt their techniques based on the material, enhancing overall print quality.

Beyond the technical skills, artistic vision plays a crucial role in successfully utilizing DTF printing. Understanding color theory, design composition, and trends within custom apparel can significantly elevate your work. Regularly experimenting with new designs, colors, and applications will not only refine your technique but also help you create standout pieces in the crowded marketplace of custom apparel.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a revolutionary custom apparel printing method that utilizes a unique process. It involves printing designs on special transfer film using eco-friendly inks, applying hot-melt adhesive to that printed film, and then heat pressing it onto fabric. This method allows for vibrant, high-quality designs on various materials.

What equipment is needed for DTF printing?

To execute DTF printing effectively, you need specific equipment including a DTF printer, which is typically an Epson model, DTF films designed for printing, hot-melt adhesive powders, and a reliable heat press. This setup ensures the successful application of DTF Transfers for stunning custom apparel.

Why choose DTF Transfers for garment printing methods?

DTF Transfers are highly advantageous due to their versatility, allowing printing on various fabric types such as cotton and polyester. They achieve intricate designs and vibrant colors, making them ideal for custom apparel printing, especially where detailed graphics are required.

How long does the heat press process take for DTF Transfers?

The heat press process for DTF Transfers typically takes around 10-15 seconds at a temperature of 320°F. This crucial step binds the design to the fabric securely, ensuring the durability and quality of the print.

Can I use DTF Transfers on different fabrics?

Yes, DTF Transfers are incredibly versatile and can be applied to a wide range of fabrics including cotton, polyester, blends, and even some specialty materials. This flexibility makes DTF printing suitable for various custom apparel projects.

What are the advantages of using DTF printing over traditional methods?

DTF printing offers several advantages over traditional methods like screen printing and DTG. It allows for intricate designs, requires less setup for small batches, and provides cost-effective solutions, especially for small orders. Additionally, DTF Transfers can be applied to numerous fabric types, enhancing creative possibilities.

| Step | Process | Key Tips |

|---|---|---|

| 1 | Design Preparation | Use graphic design software; ensure 300 DPI or higher. |

| 2 | Printing the Design | Use a compatible DTF printer; adjust printer settings accordingly. |

| 3 | Applying the Adhesive | Sprinkle hot-melt adhesive powder immediately after printing. |

| 4 | Curing the Adhesive | Use an oven or conveyor dryer to melt the adhesive. |

| 5 | Transferring to Fabric | Preheat heat press to 320°F for 10-15 seconds. |

| 6 | Peeling the Film | Let the film cool slightly before peeling. |

| 7 | Final Curing | Heat press a second time for 5-10 seconds to ensure durability. |

Summary

DTF Transfers are transforming the world of custom apparel by providing a versatile and impactful method to produce high-quality designs. By following the meticulous steps of design preparation, printing, applying adhesive, curing, transferring, peeling, and final curing, you can unlock the potential of DTF transfers. This process not only enhances the aesthetic quality of your prints but also equips you with the skills to cater to the growing demand in personalized apparel. Embracing DTF transfers allows for creativity and innovation, making it an essential practice for both hobbyists and businesses aiming for success in the custom printing market.