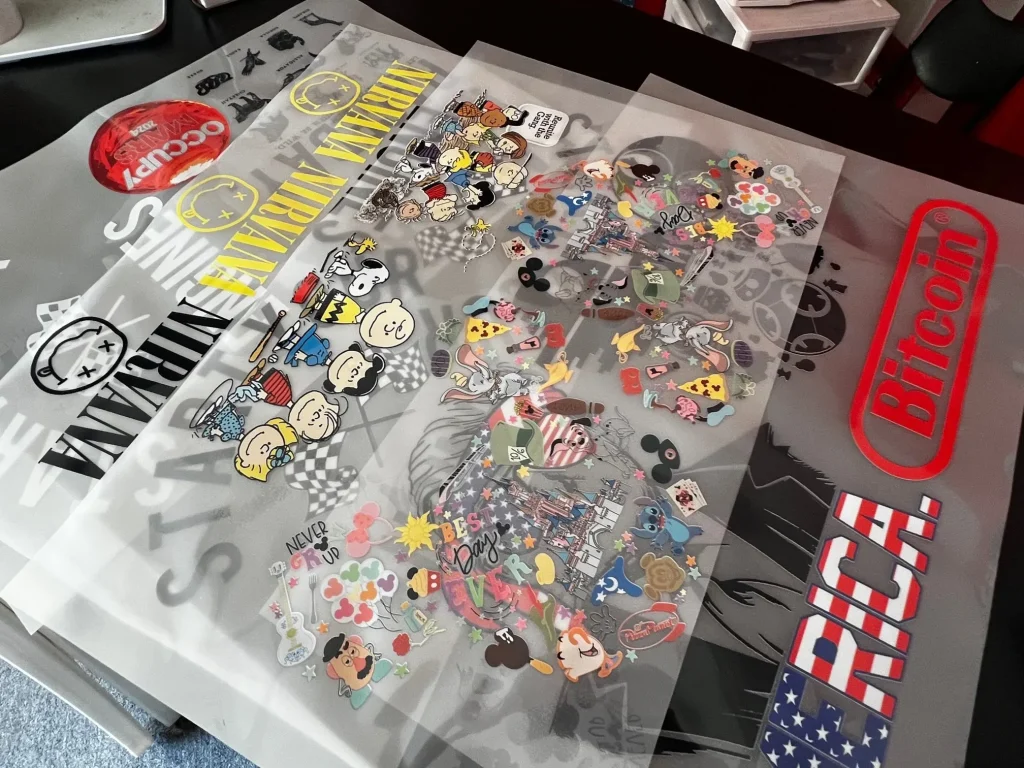

If you’re looking to enhance your custom apparel offerings, understanding DTF gang sheets is key. This innovative printing technique allows for vibrant prints while maximizing efficiency by enabling multiple designs to be printed on a single film sheet. With DTF printing, you can achieve exceptional quality and intricate details that impress your customers. In this guide, we will explore the essential steps involved in creating the perfect DTF gang sheet, helping you elevate your printing techniques and reduce waste. By mastering these methods, you can ensure that your apparel designs turn heads and boost your business.

In the realm of custom clothing production, the technique commonly referred to as gang sheet printing is rapidly gaining prominence. This method allows for the simultaneous printing of several designs on one sheet of film, effectively saving materials and costs. By utilizing DTF technology, which excels in producing brilliant color outputs and detailed artwork, you can impress clients with stunning visuals. Whether you call it gang sheet printing, film transfer, or direct-to-film printing, understanding the process behind these vibrant prints is essential. This article delves into the various aspects of preparing and executing successful custom apparel projects through optimized gang sheets.

Understanding DTF Printing Techniques

DTF printing, or Direct to Film printing, has revolutionized the custom apparel industry by providing vibrant and detailed designs that appeal to a broad audience. This technique utilizes a specialized transfer film that captures ink using a unique printing method. One of the primary advantages of DTF printing is its ability to produce vivid colors that stand out on a variety of fabrics, making it an excellent choice for designs that require precision and brilliance. Moreover, DTF prints are known for their durability, allowing for long-lasting products that can withstand repeated washes without considerable fading.

To fully leverage the benefits of DTF printing, it is important to grasp the fundamental techniques involved. This includes understanding the importance of high-quality inks and pre-treated films that facilitate better adhesion during the transfer process. Alongside these components, applying the right printer settings and thoroughly calibrating your equipment are essential steps that ensure the output retains the intended vibrancy. As the market moves toward custom apparel that emphasizes quality and detail, mastering DTF printing techniques will prove invaluable.

Benefits of Using DTF Gang Sheets for Custom Apparel

Using DTF gang sheets significantly enhances the efficiency of the printing process while ensuring high-quality outputs. By combining multiple designs onto a single sheet, businesses minimize material usage and reduce waste—an important consideration in today’s eco-conscious market. This approach not only cuts costs but also allows for a more streamlined printing setup, enabling print shops to accommodate a wider variety of designs without sacrificing production speed.

Furthermore, the strategic layout of designs on DTF gang sheets paves the way for greater creativity and innovation. Designers can experiment with different patterns, colors, and sizes, ultimately leading to unique custom apparel offerings that attract customers. This flexibility in production encourages print shops to diversify their product lines, catering to varied consumer preferences while maintaining high standards of quality.

Essential Steps to Prepare a DTF Gang Sheet

When creating a DTF gang sheet, preparation is everything. Start by ensuring that all designs are high-resolution to guarantee vibrant prints that capture your audience’s attention. Using professional software such as Adobe Illustrator or CorelDRAW can aid in perfecting your designs, allowing for precise adjustments that align with the requirements of DTF printing. Prioritize uniformity in design style and color scheme to maintain a cohesive look when printed.

Once the designs are ready, the next step is to precisely layout the images on the gang sheet. Adequate spacing between designs is crucial to create clean cuts between transfers. Utilizing grids or templates within your design software can help achieve this goal, ensuring a professional finish that minimizes errors during both the cutting and application processes.

Color Management for Vibrant DTF Prints

Achieving vibrant prints in DTF printing is heavily reliant on effective color management. The process begins with utilizing the correct color mode; designs should be created in RGB, as DTF printers convert these colors to CMYK for final printing. Ensuring the consistency of colors from the digital design to the printed output is vital, and this can be achieved through regular printer calibration and by running color checks throughout your production.

Moreover, understanding the interplay between color profiles and the quality of inks used can further enhance the vibrancy of your prints. Investing in high-quality DTF printer inks that are specially formulated for this printing technique guarantees better color saturation. This attention to detail in color management not only elevates the aesthetic of the custom apparel but also ensures that the designs remain true to the initial vision.

Optimizing Your Printing Process

The printing process itself is a critical component of producing high-quality DTF gang sheets. Attention to detail in this stage can make or break the quality of final prints. Using pre-treated films that are suitable for DTF printing helps avoid issues with ink adhesion, ensuring that designs transfer smoothly. Additionally, adhering closely to the manufacturer’s specifications regarding printing temperature and speed will lead to optimal results.

To maximize efficiency and quality, regularly check the condition of your printing equipment. Small misalignments or ink issues can lead to significant problems in print quality down the line. Incorporating routine maintenance into your workflow can help reduce these risks, allowing for a more reliable and streamlined printing process that meets both production goals and quality standards.

Effective Heat Transfer Techniques

The heat transfer stage is where the magic happens, transforming your DTF gang sheets into vibrant custom apparel. It is crucial to use the correct heating settings to ensure effective adhesion of the print to the garment. Most DTF processes recommend a heat press temperature around 325°F, applied with consistent pressure for approximately 10 to 15 seconds. This step requires precise execution to ensure that each design adheres properly without damaging the fabric.

Additionally, allowing the garment to cool completely before peeling the film is a critical step often overlooked. This cooling period enhances adhesion, thus preventing lifting during wear. Once the film is removed, inspect each garment for any imperfections, ensuring that your final product meets the high standards expected by customers. Implementing these effective heat transfer techniques can significantly elevate the quality of your custom apparel.

Frequently Asked Questions

What is a DTF gang sheet and why is it important for DTF printing?

A DTF gang sheet is a method used in DTF printing to print multiple designs on a single film sheet. This technique is important because it minimizes waste, reduces costs, and maximizes efficiency in the custom apparel production process by allowing several designs to be printed at once while maintaining high-quality outputs.

How can I prepare designs for my DTF gang sheet to ensure vibrant prints?

To prepare designs for your DTF gang sheet, use high-resolution images and design software like Adobe Illustrator or CorelDRAW. This ensures clarity and color vibrancy, which are essential for achieving the intricate details and vivid colors that DTF printing is known for.

What steps should I follow to layout designs on a DTF gang sheet?

When laying out designs on a DTF gang sheet, ensure adequate spacing between each design to facilitate cutting and application. Utilizing a grid or template can help maintain professional alignment and spacing, resulting in a more polished final product.

What are the best practices for color management in DTF printing?

For effective color management in DTF printing, design using the RGB color mode as it translates best to CMYK for printing. Regular printer calibration is also crucial to achieve consistent and accurate color outputs that match your original designs.

What materials are essential for the DTF printing process?

Essential materials for successful DTF printing include high-quality DTF printer inks, pre-treated film specifically designed for DTF printing, and a reliable heat press. These components ensure optimal ink adhesion and vibrant, durable prints on custom apparel.

How do I ensure proper adhesion of DTF prints to garments during the heat transfer process?

To achieve proper adhesion during the heat transfer process, set your heat press to around 325°F and apply consistent pressure for 10-15 seconds. It’s important to allow the garment to cool completely before peeling off the film to enhance adhesion and minimize lifting.

| Step | Description |

|---|---|

| 1. Design Preparation | Prepare high-resolution images and use design software like Adobe Illustrator, CorelDRAW, or Inkscape for layout adjustments. |

| 2. Layout on Gang Sheet | Arrange designs with adequate spacing using a grid layout or template to ensure professional placement. |

| 3. Color Management | Design in RGB mode and calibrate printers to ensure color accuracy for vibrant outputs. |

| 4. Printing Process | Use high-quality DTF inks and pre-treated film while following manufacturer printing specifications. |

| 5. Heat Transfer Process | Utilize a heat press at 325°F for 10–15 seconds, allowing the garment to cool before peeling the film. |

| 6. Final Touches | Inspect prints for adhesion and quality. Implement consistent quality control practices. |

Summary

DTF gangsheet is a crucial element for producing vibrant and high-quality prints in the custom apparel industry. By following a structured step-by-step tutorial, you can craft gang sheets that not only enhance the vibrancy of your designs but also optimize the overall printing process. Remember to prepare designs accurately, manage colors effectively, and pay attention to both the printing and heat transfer processes for the best results. As the demand for customized clothing rises, mastering DTF gang sheets will significantly elevate your offerings and ensure customer satisfaction.